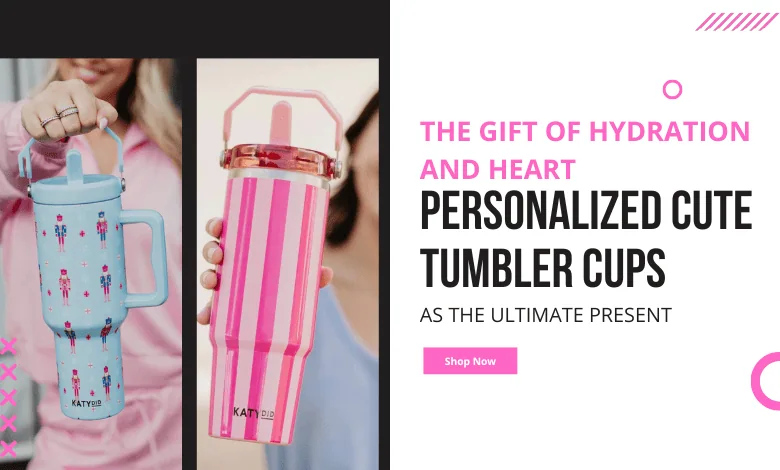

The Gift of Hydration and Heart: Personalized Cute Tumbler Cups as the Ultimate Present

In the sprawling landscape of gift-giving, the challenge is always to find an item that is both genuinely useful and deeply personal. It must move beyond the realm of generic trinkets and establish itself as a thoughtful keepsake—a tangible reminder of a special relationship or event. In recent years, one item has risen to prominence, flawlessly blending functionality with custom style: the personalized cute tumbler cups. Far from being just another piece of drink ware, these customized cups have become the quintessential birthday surprise and the undisputed champion of bridesmaid gifts, offering a perfect, everyday blend of practicality and personality.

The tumbler cup’s success as a gift stems from its central role in modern life. Whether a person is heading to a spin class, commuting to work, or simply staying hydrated at their desk, a high-quality, insulated tumbler is a constant companion. The personalization factor is what elevates it from a mere utility item to a cherished gift. By adding a name, a meaningful date, a title, or a unique design, the giver transforms a simple cup into a personal statement, demonstrating a level of thoughtfulness that resonates far more powerfully than a mass-produced item.

The Allure of Practical Personalization

The best gifts are those that are used regularly, integrating themselves seamlessly into the recipient’s daily routine. A tumbler cup perfectly fulfills this requirement. It encourages healthy hydration, reduces the need for single-use plastics, and serves a practical purpose throughout the year, keeping cold drinks frosty in the summer and hot beverages steaming in the winter.

The “cute” factor, driven by endless customization options, is what makes it a joy to receive. Modern tumblers come in a spectrum of vibrant colors, sleek finishes, and sizes, allowing the giver to match the cup to the recipient’s personal style. The addition of personalized elements—a beautifully scripted monogram, a playful nickname, or a stylized floral design—shows the recipient that the gift was chosen and created specifically for them. This level of personalized utility suggests that the giver truly pays attention to the recipient’s daily life and preferences.

The Ultimate Birthday Surprise: Celebrating Individuality

As a birthday gift, the personalized tumbler is a strong choice because it can be finely tuned to reflect the recipient’s current passion or personality. The customization goes far beyond a simple name. Givers can tailor the tumbler to reflect a new job title, a favorite quote, an inside joke, a college logo, or a specific hobby like hiking, knitting, or gardening.

This high degree of specificity transforms the cup from a simple gift into a personalized narrative. It signals that the giver recognizes and celebrates the recipient’s individuality. For milestones—a 30th birthday, a graduation, or a promotion—the personalized tumbler acts as a functional trophy, a daily-use item that commemorates an achievement. It avoids the clutter of novelty gifts while retaining the heartwarming intimacy of a handcrafted item. For busy parents or working professionals, the gift of a high-quality tumbler is an acknowledgment of their constant movement and a gentle reminder to take care of themselves.

Quality and Durability: An Investment in Longevity

The perceived value and longevity of any personalized gift are paramount. The popularity of these tumblers is intrinsically linked to the high quality of modern stainless steel, insulated drinkware. The best options are typically double-walled and vacuum-sealed, providing superior temperature retention that generic plastic cups simply cannot match.

When selecting a tumbler, the giver should prioritize features like leak-proof lids, durable powder-coat finishes (which resist chipping and fading), and food-grade stainless steel interiors. A durable cup ensures that the personalization—the very heart of the gift—remains vibrant and intact for years. This commitment to quality translates into a gift that is not disposable; it is designed to last and be used daily, ensuring that the memory of the occasion and the thoughtfulness of the giver endure.

Conclusion: The New Essential Keepsake

The rise of the personalized cute tumbler cup is a testament to the enduring desire for gifts that are both meaningful and practical. As a birthday present, it is a celebration of the individual’s journey and personality. As a bridesmaid gift, it is a perfect symbol of unity, gratitude, and a shared, unforgettable experience. By blending the functionality of modern insulated drinkware with the heartfelt intimacy of custom design, these tumblers have cemented their place as the ultimate essential keepsake, proving that the most cherished gifts are those that effortlessly blend utility with a personal touch.

Enjoyed this? Dive into more articles that challenge your thinking and ignite your motivation.