THE BEST WAY TO TEACH YOURSELF PIANO

Many people who wish to get piano lessons think that learning the music notes and practicing the instrument for hours is not their cup of tea. Kick out your negative thoughts and reach out to a good music instructor Milton to fulfill your dreams with an open mind. Yes! Learning any musical instrument will take a considerable amount of time. It is not easy to master music. But, it doesn’t have to be as difficult as you think, and it will not take you forever to start playing your tunes.

GUIDE TO LEARN THE PIANO YOURSELF

Many people grow old with an unfulfilled wish of learning music. No need to wait too long if learning to play the piano is on your bucket list. How old are you? Doesn’t matter! You can get good piano lessons in Milton at any age. These steps should help you to learn to play the instrument the quickest possible.

Get a piano

The initial step to learning piano is to find an instrument on which you can learn and practice your skills. You don’t need to buy the instrument. Instead, borrow it from any one of your friends or family members. Getting the instrument on rent is also a good idea if you are unable to buy it.

If you are eventually planning to buy your piano, figure out your budget and shop accordingly. Based on your budget, get an acoustic piano or a digital keyboard. If you are getting a keyboard, make sure it mimics a piano. It should have eighty-eight keys and should mimic the tone of an authentic acoustic piano. Some beginner keyboards come with instructional materials that can help you learn to play the piano.

Learn basic piano lessons

A good piano teacher will provide you with the basics of piano lessons before you start your journey to mastering the instrument. However, if you are learning the instrument independently, take your small steps one after another.

- Know the instrument appropriately. Pay attention to the middle keys, the flat keys – i.e., the left black keys, the sharp keys -i.e., the right black keys, and the bass and high tones.

- Learn the middle C. It is the base where you start learning to play the piano.

- Grasp the basic keys. Learn the white keys, the C-D-E-F-G-A-B. The black ones are the accidentals that produce a sharp or flat sound when you press them.

- Get precise knowledge about the language of music. A few basic music terms are worthwhile. It is ideal for getting basic music lessons from a good music school.

Grasp the major keys

Learning the major keys is the most important step in learning piano, whether you are learning independently or looking to find a piano teacher. Try out a numbering scheme to learn the major keys, like the 1 = the middle key C, 2 = D, 3 = E, 4 = F, 5 = G, 6 = A, 7 = B, and 8 = the higher key C

The numbering scheme is a good idea to learn to play basic songs. Understanding scales is the best way to learn major keys. An experienced piano teacher will advise you to start with the main keys and then move on to the minor ones.

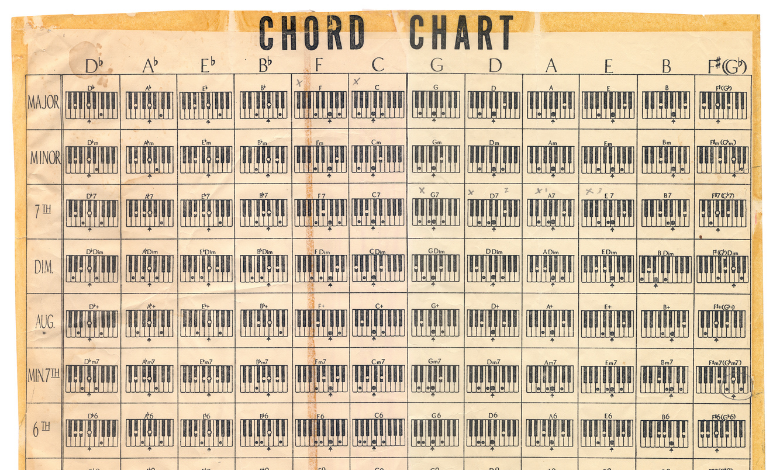

Learn common chords

You can learn a few common music chords even if you haven’t learnt to read the music. There are two chords in music; major and minor. Major chords use three keys: the root, third, and fifth. Minor chords are composed of the root, the flat third key, and the fifth key. There are twelve major and twelve minor piano chords. Once you grasp them, you can move on to the advanced chords; the diminished, augmented, seventh, sixth chords, and more. However, start with the basic major and minor chords.

The internet can be an invaluable resource while teaching yourself how to play the piano. Reach out to a good music school and start getting the best piano lessons for beginners at an affordable fee. You can also get downloadable chord sheets that can help you play your favorite music recordings through the net.

Learn piano patterns

Music has different patterns. As you start educating yourself about the piano, you will notice those patterns. For instance, some chords repeat in certain songs. Once you recognize the patterns, it will be easy to learn how to play the songs. Likewise, it will become easy to learn the melodies and the baselines of your favorite songs if you pay attention to their patterns.

Every song has a unique pattern. These patterns are referred to as music vocabulary. They are vital to understanding the music. Patterns are there in rhythm and tone. Even left-hand accompaniment patterns are also there.

Be active while listening to music. Get a recording of the music piece you wish to learn. See if you can spot the patterns. Then try to play the pattern on the piano. Keep these patterns in mind, as they will surely come up again in other pieces. Besides, these patterns will also be important while learning to read the music sheets.

Learn finger patterns

The most crucial element when learning to play the piano is fingering. While playing the piano, you need to be familiar with where your fingers should go. Grasping scales is the best way to learn proper finger placement. Learn the major scales first and then the minor scales. As mentioned before, numbers can help you determine proper finger placement. Number your left hand for the thumb to the little finger with one through five; same with the right hand.

The right-hand fingering will be 1-2-3-1-2-3-4-5 and backpedal 5-4-3-2-1-3-2-1. To play the second one, cross your thumb underneath your third finger. And while going down the scale, cross over your thumb with your third finger to reach the second one.

Practice fingering on your right hand and then left; this will help you learn to play scales with both your hands. In addition, finger exercise is a good thing to consider establishing your fingers’ strength and preparing them to play the piano.

Learn to read the music

Learning to read the music is vital to learn how to play the piano. However, it is easy once you master the basic principles of piano playing.

First, you will need to learn the names of left and right-hand staff, i.e., bass clef and treble clef. To remember where each note is on the treble chord, you can use mnemonics. Indeed, learning to read music is not just about the notes. There are various other aspects to consider. Learning to read rhythm is also vital. It is important to pay attention to the notes while you first start learning to play the piano. The rhythm will come later on as you progress. While you are learning to read music, the fundamental steps you will need to take would be to learn the right way to recognize music patterns, grasp major chords, and fingering. The combined knowledge you gain should allow you to use the sheet music to your advantage.

Once you learn to read music and play the instrument simultaneously, get sheet music with different difficulty levels. You can even get them online. Learning some of these can make you sound like a piano pro to your family and friends.

Practice

Anything you learn needs actual practice; so does the piano. Spare at least half an hour for practicing daily. If not every day, practice a week thrice. Start practicing from scales that will help you recognize keys, learn fingering, and make you feel more fluent while playing the piano.

Start your practicing session with some easy songs you like. Yes, initially, you might not be ready to play a song. However, there are some easy songs you can play on the piano. Even if you don’t have the instrument, you can practice the piano. Try to refer to sheet music and notes in your spare time.

Do not expect too much at the initial stage. Unrealistic expectations will cause you to lose your patience and give up more quickly. But, on the other hand, slow progress is not the sign of weakness. So don’t get discouraged. As long as the learning is going on, you have the chance to be a pro pianist.

Record yourself once a week. Listening to your piece of music will help you stay motivated. May it be a visual or audio performance, reviewing your work will be a great practice.

Enroll yourself to a good music school

No matter how hard you try, a professional piano teacher could be of great help. Consider enrolling yourself to the best music school in Milton, whether you are looking for a music teacher in person or virtual if you find any difficulty learning to play the instrument. It is possible to teach yourself the instrument, but it will be much easier if you have someone to correct your mistakes and praise your achievements. A piano instructor can help you get things right the first attempt and will not make you retrain bad habits you might acquire while learning.