Controlling Concrete Dust Keeps the Concrete Workers Safe

Perpetual exposure to airborne concrete and silica dust (crystalline silica) is likely to pose substantial health-related risks, and with time, it can even be riskier. To keep the concrete workers safe on the construction sites, proper control of all silica-containing concrete dust exposure is the most crucial safety measure that every construction company should take and protect their workers. This is where Spillrite silica-concrete dust pneumatic vacuum plays a vital part in health safety.

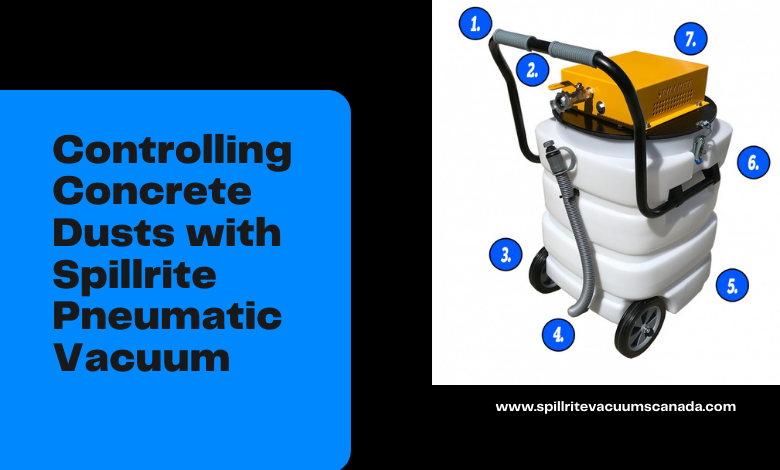

Controlling Concrete Dusts with Spillrite Pneumatic Vacuum

Drilling, sawing, grinding, and demolition processes at the construction sites spark off unhealthy and hazardous loads of dust particles. The tasks are commonly performed on construction materials that include bricks, concrete, mortar, and stones. These materials contain a specific amount of crystalline silica.

In concentrated form, crystalline silica in air, a small risk to the workers’ health, but once cut, it can generate some dust particles that can drive into the worker’s breathing space. The silica dust, once it is airborne, can particularly get more harmful.

Construction companies need to create and implement an effective exposure control plan that can lower the workers’ exposure to silica dust in the most efficient way. This plan should consist of the amount of silica dust that the workers will be exposed to, allowing workers to access the regions in which the silica exposure is over the permitted exposure limit, and ultimately providing each worker with the routine medical examinations exposed to the silica dust regularly.

Besides, the construction workers should also get a precise education on the health-hazard of silica dust. The construction employers should also make the workers learn the correct ways to operate and clean the cleaning equipment like the HEPA Filtered vacuums used to limit the exposures.

There are various ways to consider to prevent or lower silica dust exposure. Spraying water on the concrete and stone before grinding or cutting is the most common prevention method that helps to eradicate silica dust on the site.

This approach is not the perfect dust control method but can effectively work when paired with a glass silica recovery pneumatic vacuum system. Vacuum devices can provide a precise shield to the workers and everyone at the site against dust and be used while cleaning the worksite.

Eliminating concrete dust with industrial vacuum cleaners

Handling fine silica dust needs a certified, multi-stage filtration system. A system that filters the dust, and as the dust passes through the machine, gets retained. Hepa filtered vacuums are particularly high-efficiency vacuum systems. The tool is most useful for effectively lowering exposure to airborne silica dust on dusty regions like construction work sites.

HEPA filters are the best options to eliminate concrete dust since they are equipped with a mechanism that collects and retains the silica dust and doesn’t swarm it around the workplace. In addition, they are apt to retain circa 99% of the dust particles. Most importantly, they should be at the last phase of the filtration system and prevent minute dust particles from getting back through the machine.

HEPA filtered vacuums are beneficial for many companies. However, with Jobsite cleaning, they are also efficiently used in many other ways to lower silica exposure limits in workers.

Power tools of industrial vacuum cleaners

While drilling, grinding or cutting, the powerful tools in the HEPA filtered vacuums can, in the blink of an eye, suck the dust generated on the construction site. Concrete grinders coupled with vacuum attachments are especially beneficial since they remove silica dust from the construction site.

Complex areas

Some spots like overhead beams and pipes are difficult to clean since the spaces are harder to reach. The dust piled up in these areas can contribute to fire and also health hazards. However, it is crucial to clean these spots properly. Only a specific type of vacuum cleaner can clean these complex spots easily.

Purifying workers’ attire

Before switching off work and reaching other locations like the break area or home, each worker must clean their clothes properly and eliminate the dust residue. Industrial HEPA filtered vacuums can effectively remove silica dust settled on the workers’ clothes as well. However, construction companies should have the system arranged at the exit points of the site to make sure that all workers can clean their attire while leaving the site.

Industrial vacuum cleaners are particularly manufactured to provide companies with specific functions and facilitate the needs of some particular businesses and facilities. There are various vacuum models available, ranging from electric to pneumatic and static to mobile. However, it is crucial to make an informed decision when buying one for your type of facility.